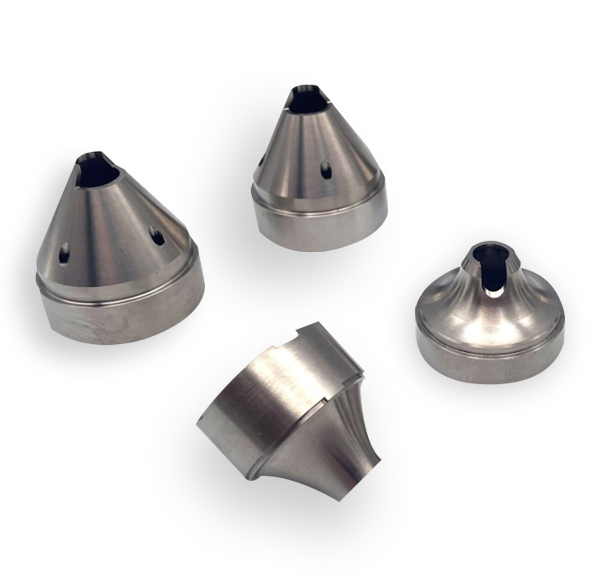

Titanium Powder Metallurgy Suppressor Baffles

Lighter. Cheaper. Better!

Suppressor Baffles

Material/Machine Use

Up to 80% Reduction in Raw Material Usage

Cost Savings

Typically, Over 30%

Material Performance

ASTM B988 Tensile Properties

Weldable

Laser or TIG weldable

Performance Advantage

Increased High-Temperature Properties

Mass Production Process

Tooling Required (starting at $5,000)

Minimum Monthly Volume = 500 parts per month

The Perfect PMTi Part

- Radial symmetry

- High Annual Volume (>10,000/year)

- Low Effective Density

- Baffles are an excellent application

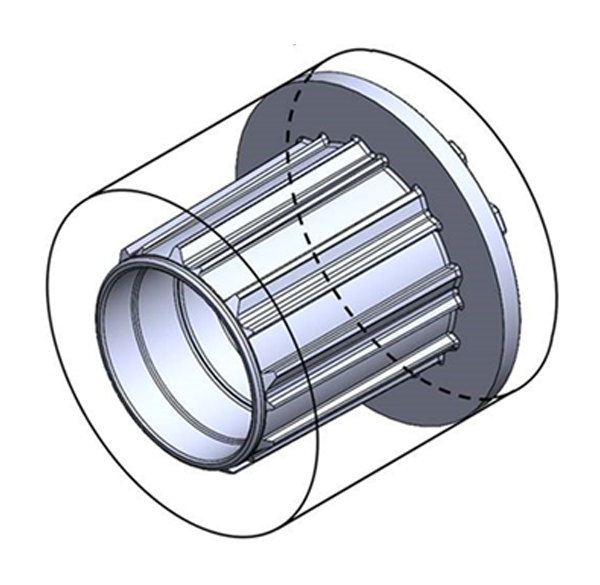

The Concept of “Effective Density”

The less material in the total “envelope” of the part, the more material cost savings are possible with powder mettallurgy.

In this example, the final part only occupies 6% of the total envelope part and weighs 5 g.

Transforming Titanium Baffle Manufacturing [Free Resources]

Unlock the potential of titanium suppressor baffles with insights from industry expert Joe Grohowski of Praxis Technology.

✅ Get access to our 25-minute webinar recording, plus get these free additional resources

📄 Titanium Suppressor Baffle Manufacturing Guide

📊 Cost and Timeline Optimization Checklist

🔬 Advanced Materials Comparison Chart

Economical Manufacturing of Suppressor Baffles

.png)

- Near net-shape fabrication reduces material costs

- Meets mechanical requirements of ASTM B988

- Product specific benefits for suppressor applications

Book a meeting with our CEO Joe Grohowski to learn more!

——— ABOUT

Praxis Technology

- Experts in Titanium Powder Metallurgy (PM)

- Leader in titanium baffle production via PM

- Manufacturing titanium implants via PM since 2008

- Tier 1 supplier to major OEMs

- 50+ medical implants in production

- >750,000 implants in service

Manufacturing Technologies

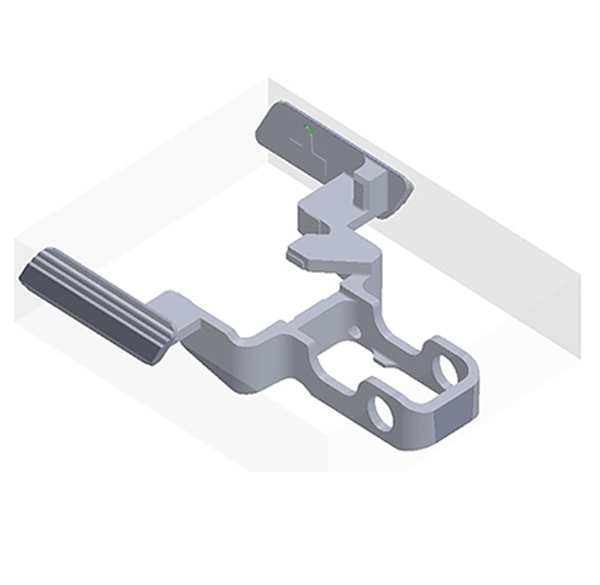

- Titanium MIM: Metal injection molding of small complex medical implants

- Porous Titanium: Patented bone ingrowth material duplicating bone porosity

- PMTi: Low-cost Compacted Ti-6Al-4V

- TiRx: Proprietary heat treatments for MIM and additively manufactured parts

PMTi Production Timeline & Costs

Manufacturing Methods Comparison

|

PRAXIS PMTI-6AI-4V |

INVESTMENT CASTING |

CONVENTIONAL MACHINING |

|

|

Per part cost |

Low |

Low |

High |

|

Creep performance |

High |

Low |

Low |

|

Upfront Tooling cost |

Low |

High |

n/a |

|

Weldability |

Good |

Poor |

Good |

|

Net-shape surface |

Good |

Poor |

n/a |

PMTi - A Material Advantage for Suppressor Baffles

Slightly elevating the oxygen increases tensile properties via interstitial strengthening.

This strengthening mechanism is compositional rather than microstructural and persists at higher temperatures, delivering improved creep performance over conventionally formed titanium

Lamellar structure provides better creep strength than wrought or cast product.

Elevated oxygen also provides slight increase in hardness (~40HRC), which can improve wear resistance.

Tensile strengths compare favorably with ELI and NI Grades, elongation slightly less.

.png?width=768&height=612&name=COMPARISON-of-creep-graphic_FINAL_v2-768x612%20(1).png)

Material Compliance: PMTi Ti-6Al-4V

Praxis Typical PM values compare well with standard specifications

Standard PM material is best value for suppressor components

Heat treated PM material has exceptional performance

Praxis’ typical values surpass both the cast & wrought strength specifications

|

|

STANDARDS | SpotlightWP | ACTUAL (Typical) | Add New | |

| ELEMENT/PROPERTY | ASTM F381 Ti-6AI-4V Wrought |

ASTM B367 Ti-6AI-4V Cast |

ASTM BP88 Ti-6AI-4V PM |

Praxis PM Ti-6AI-4V Standard |

Praxis PM Ti-6AI-4V Standard |

| MECHANICAL PERFORMANCE | 29+ | 4 | 1 | 33 | Add New |

| UTS MPa (kis) | 895 (130) | 860 (125) | 985 (130) | 1070 (155) | 1138 (165) |

| YS MPa (ksi) | 828 (120) | 758 (115) | 828 (120) | 945 (137) | 1034 (150) |

| Elongation % | 10% | 8% | 10% | 12% | 16% |

| Reduction of Area | 25% | 14% | 25% | 25% | 40% |

| CHEMICAL REQUIREMENTS | Add New | Add New | Add New | Add New | CHEMICAL REQUIREMENTS |

| Nitrogen | <0.05% | <0.05% | <0.05% | <0.03% | <0.03% |

| Carbon | <0.08% | <0.10% | <0.08% | <0.02% | <0.02% |

| Hydrogen | <0.0015% | <0.0015% | <0.0015% | <0.01% | <0.01% |

| Iron | <0.40% | <0.30% | <0.40% | <0.20% | <0.20% |

| Oxygen | <0.20% | <0.20% | <0.30% | <0.34% | <0.34% |

| Aluminum | 5.5-6.5% | 5.5-6.75% | 5.5-6.75% | 5.5-6.75% | 5.5-6.75% |

| Vanadium | 3.5-4.5% | 5.5-6.75% | 5.5-6.75% | 5.5-6.75% | 5.5-6.75% |

| Titanium | Balance | Balance | Balance | Balance | Balance |

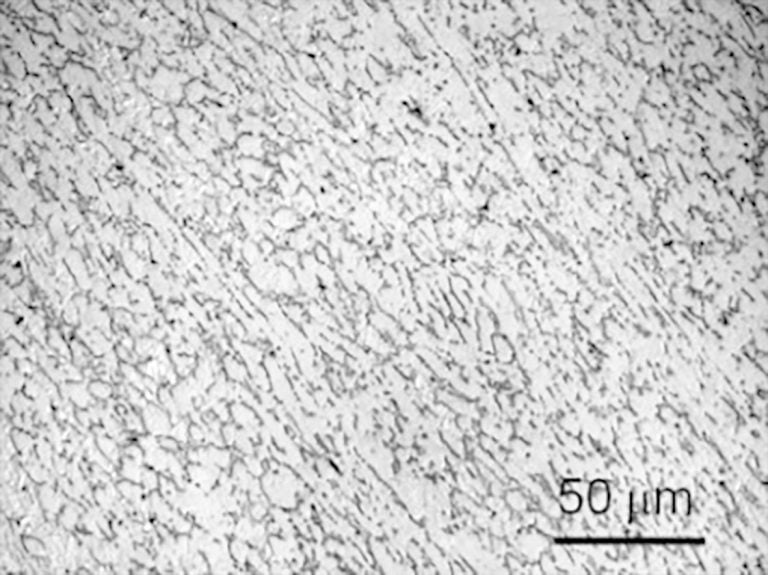

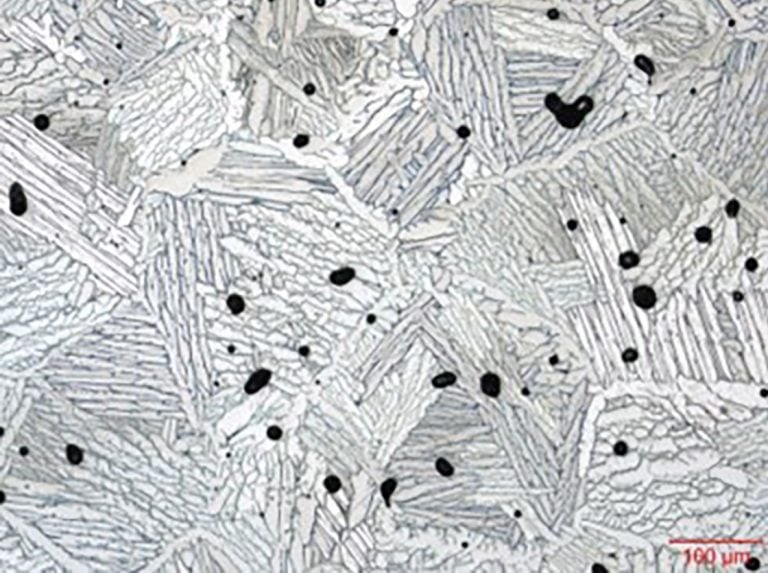

Metallographic Comparison

Wrought Ti-6AL-4V

- Fine grains

- Directionality from working

- Many microstructures possible based on thermal & mechanical history

PMTi Ti-6Al-4V – HIP’ed

- Coarser grains

- Coarse lamellar structure

- Alpha colonies with grain boundary alpha of similar size

- Intergranular beta

HIP’ed to Achieve Full Density

As-sintered

As-Sintered >96% Dense

Hot Isostatically Pressed

100% Dense

Market Focus

Leaders in Highly Regulated & Performance Critical Markets

Defense

- FFL

- ITAR Registered

Aerospace

- AS9100D

- ISO 9001 Certified

Medical Device

- ISO 13485 Certified: Production

- FDA Registered

- CFR 21 Part 11 Compliant

- FDA Master File

- Product certified to ASTM F2885-17